Application of helium mass spectrometer leak detector in vacuum coating machine equipment

Date:2022-03-30 Views:2968

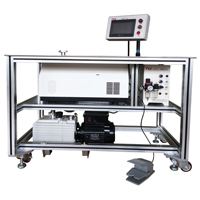

Coating equipment should operate under high vacuum conditions. The quality of the vacuum value can directly affect the quality of the coating on the surface. Vacuum coating equipment has the problem of poor airtightness. If an airtightness test can be carried out after the maintenance of the coating equipment, many unqualified products can be avoided, achieving the effect of cost savings.

The Nuoyi helium mass spectrometer leak detector uses helium gas as the tracer gas, with a minimum leak rate of less than 5E-13 Pam³/s. It is safe and environmentally friendly. There is no need to shut down the equipment during leak detection. Just connect the leak detector to the bypass of the mechanical pump, and the detection can be carried out quickly and effectively.

Anhui Nuoyi Technology provides a complete product line of helium mass spectrometer leak detectors, which are widely used in helium leak detection in the vacuum coating industry. From portable helium mass spectrometer leak detectors to leak detection modules, it provides negative pressure leak detection (vacuum method) and positive pressure leak detection (sniffer probe method) to meet various applications.

More Application Cases of Helium Mass Spectrometer Leak Detectors >>

In view of the confidentiality of customer information, if you need to learn more about the cases of helium mass spectrometer leak detectors, you can contact us:

Contact Tel. & Fax: 0551-65533775

National Unified Service Hotline: 400-1677-880

Product Inquiry: Mr. Cao, 186-5697-1155 (WeChat)

Public Security Network Security Record in Anhui Province No. 34010302001915

Public Security Network Security Record in Anhui Province No. 34010302001915