Technical Support

Which helium mass spectrometer leak detector is suitable for me? How to choose?

Date:2022-03-18 Views:4562

How to select a helium mass spectrometer leak detector depends on the customer's needs:

-

- Application type? (For example: production, maintenance, etc.) - Dry/traditional oil pump?

-

- Performance? (The time required to enter the leak detection mode, sensitivity, response time, recovery time, primary pumping capacity).

-

- Weight and size.

The performance of the helium leak detector is mainly measured by the following parameters:

> Primary pumping capacity: (m3/h)

> The maximum allowable inlet pressure for detection: (mbar)

> The time required to enter the detection mode: (s)

> Helium pumping speed: (l/s)) Sensitivity, the lowest detectable helium signal: (mbar.l/s)

> Response time: (s)

> Recovery time: (s)

Primary Pumping Capacity:

> It will determine the time to enter the detection mode. It will determine whether it is possible to perform detection only with the leak detector (whether an auxiliary pump is needed).

The Maximum Allowable Inlet Pressure for Detection:

> It will determine the time required to enter the detection mode.

The Time Required to Enter the Detection Mode:

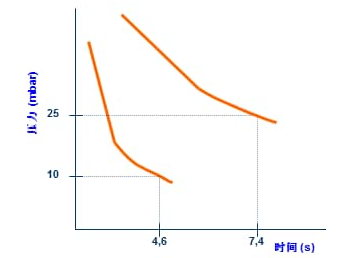

It is jointly determined by the primary pumping capacity and the maximum allowable pressure for detection.

Example 1: The maximum allowable pressure for detection = 10 mbar, primary pumping capacity = 10 m3/h, and the time required to enter the detection mode (rough detection) = 4.6 seconds.

Example 2: The maximum allowable pressure for detection = 25 mbar, primary pumping capacity = 5 m3/h, and the time required to enter the detection mode (rough detection) = 7.4 seconds.

In the above examples, the volume of the tested part is 10 liters.

Other parameters that may affect the detection time: Degassing of the cavity and very large leaks.

> For example: Water: 1g of water at a pressure of 1000 mbar will release approximately 12,444 liters of water vapor at a pressure of 10-1 mbar.

The material itself (has gas adsorbed on the surface or inside).

Air leakage: Welding problems, threaded connections, grooves for fixing O-rings, etc.

Others: Oil, grease, solvents, etc.

A high helium pumping speed means:

Fast response time, fast recovery time, the ability to quickly reach a low helium background, and the ability to test large-volume tested parts while maintaining high sensitivity.

Response Time:

When spraying helium on the tested part, the mass spectrometry chamber cannot detect the helium signal immediately:

The response time depends on the volume V of the tested part and the helium pumping speed S at the connection of the tested part of the entire system. The response time V/S reflects the time required to obtain 63% of the helium signal.

Fast Clearance Time/Recovery Time

The recovery time means the time required for the leak detector to return to the required sensitivity after obtaining a helium signal.

Anhui Nuoyi Technology provides a complete product line of helium mass spectrometer leak detectors, from portable helium mass spectrometer leak detectors to leak detection modules, providing negative pressure leak detection (vacuum method) and positive pressure leak detection (sniffer probe method) to meet various applications. It can meet the needs of single-machine leak detection and can also be integrated into the leak detection system or PLC. For more helium detection technologies, you are welcome to leave a message for discussion!

Part of Atlas Copco Group

Public Security Network Security Record in Anhui Province No. 34010302001915 Product: Helium Mass Spectrometer Leak Detector

Public Security Network Security Record in Anhui Province No. 34010302001915 Product: Helium Mass Spectrometer Leak Detector

Some materials are sourced from the Internet. If there is any infringement, please contact us for deletion.